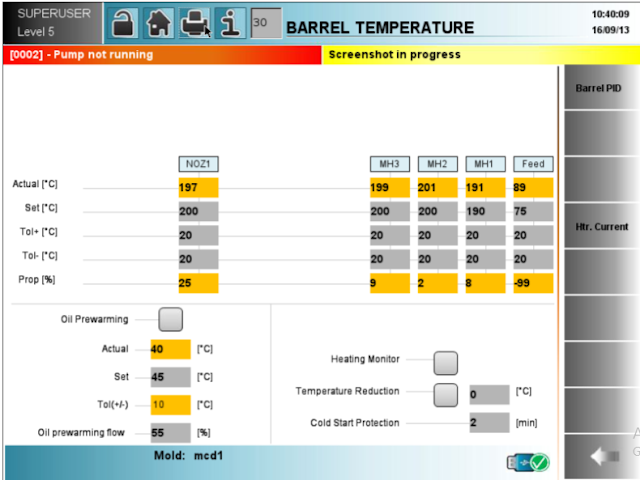

BARREL TEMPERATURE

The barrel heating has a soft switch on the IBED for switching it on. Pressing the switch again will switch the heaters off. Each heating zone has a set value, an actual value, positive and negative tolerances, and an actual percent of utilization. If the value of zero is set for a particular zone, then that zone is omitted from the monitoring process. Appropriate positive and negative tolerances can be set quite independently and separately for each zone. When the tolerance band is re-entered then screw rotation is prevented for the set cold start protection time. If the temperature rises above the upper tolerance during Automatic operation, then the alarm CYLINDER TEMPERATURE TOO HIGH is set and ALARM PRESENT appears on the top of the screen and heating is switched OFF. When the temperature sinks to below the lower tolerance, then the machine continues until the cycle is completed (as in semi-a...